EU Projects

Innovative, low-waste technology for machining large-sized rings

Project under Measure 1.1: R&D projects of enterprises, Sub-measure 1.1.2: R&D works related to the creation of a pilot/demonstration installation for the Intelligent Development Operational Programme 2014-2020 co-financed from the funds of the European Regional Development Fund. Project co-financing agreement signed with the National Centre for Research and Development in Warsaw on 1st July 2016 (agreement POIR.01.01.02-00-0079/16).

Project objectives

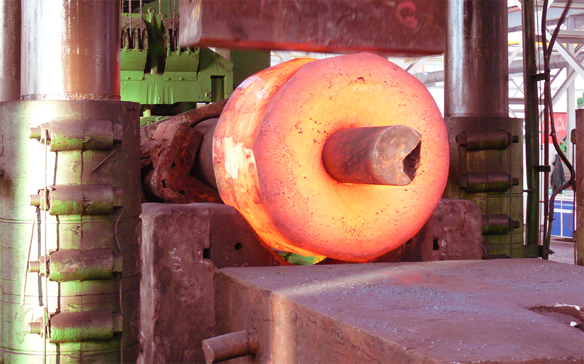

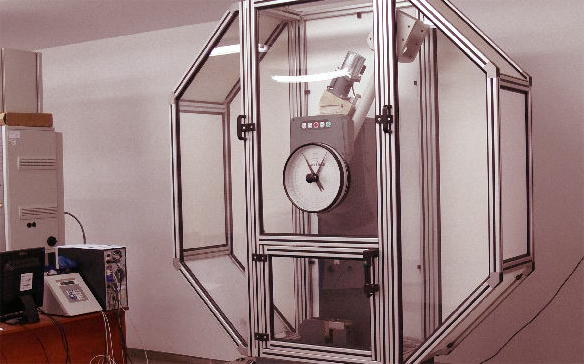

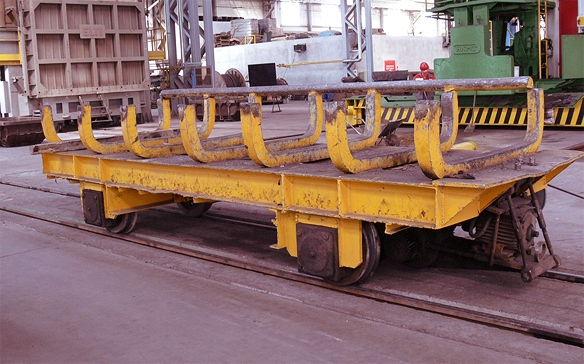

As a result of the project, the Company will develop and verify an innovative, low-waste technology of machining large-sized rings using the rolling and forging method in actual conditions. The obtained solution will allow the Company to offer rings with a diameter of up to 4,000 mm and a height of up to 800 mm with a complex cross-sectional geometry, made of a whole spectrum of steel grades, including special steels and non-ferrous metal alloys. The products will be manufactured as almost finished products with minimal allowance. The developed demonstration processing line together with a unique flaw detection station and an automated material transfer system will enable production of ring products without mechanical processing (or with minimal processing) characterized by a uniform structure of the material across the whole cross-section..

The implementation of the project is a response to the market demand submitted by entities operating in industrial sectors resulting from the development of construction materials and the growing demand for increasing the functional properties of ring products.

As a result of performed works, an advanced solution with a high commercial potential will be delivered to the global market. The implementation of project results into the Company's operations will allow it to achieve a significant competitive advantage and will enable it to expand its operations on new target markets. The implementation of the project will contribute to the implementation of innovative solutions resulting in an increase in Polish export, improvement of international competitiveness and innovativeness of the Polish economy, as well as Polish know-how concerning the methods of machining large-sized rings.

Planned effects

As a result of the project, a low-waste technology of machining large-sized rings will be developed, meaning that the efficiency of using input materials will increase. The rings will be very similar in shape to the final product, reducing machining to a minimum. This will reduce the size of the charge, directly affecting the heating time and reducing the energy consumption of the process. Reducing the heating time will also result in savings in the charge material by reducing the amount of scale, i.e. the layer of material on the surface of oxidized and burned cast ingot. The implementation of the test results will reduce the amount of energy necessary to heat the charge material, and the automation of the process will enable manufacturing a complete ring in a “single heat”. The above will contribute to the reduction of CO2 emissions into the atmosphere by about 20%.

The development of the technology being the subject of the project will enable reducing the volume of technological waste in the form of scale, chips, and web. Segregation of waste will increase the reuse of waste by about 3% as a result of its recycling. Moreover, according to analytical and laboratory tests, the production of a ring using the innovative method will increase its service life by up to 15%.

Press shop

Press shop

Heat Treatment

Heat Treatment

Mechanical Working

Mechanical Working

Laboratory

Laboratory

Warehouse

Warehouse